管线管

类别:

产品规格

| 管线管尺寸、单位重量 API SPEC 5L、GB/T9711、GOST 20295 | |||||||||||||||

| 外径 | 壁厚 | 单重 | 钢级 | ||||||||||||

| in. | mm | in. | mm | Ib/ft | kg/m | A25 | A | B | X42 | 46 | 52 | X56 | X60 | 65 | K70 |

| L175 | L210 | L245 | L290 | L320 | L360 | L390 | L415 | L450 | L485 | ||||||

| 1.315 | 33.4 | 0.133 | 3.4 | 1.68 | 2.52 | ● | ● | ● | |||||||

| 0.179 | 4.5 | 2.17 | 3.21 | ● | ● | ● | |||||||||

| 1.66 | 42.4 | 0.140 | 3.6 | 2.27 | 3.42 | ● | ● | ● | |||||||

| 0.191 | 4.9 | 3.00 | 4.50 | ● | ● | ● | |||||||||

| 1.90 | 48.3 | 0.145 | 3.7 | 2.72 | 4.07 | ● | ● | ● | |||||||

| 0.200 | 5.1 | 3.63 | 5.43 | ● | ● | ● | |||||||||

| 2-3/8 | 60.3 | 0.083 | 2.1 | 2.03 | 3.02 | ● | ● | ● | ● | ● | ● | ● | |||

| 0.109 | 2.8 | 2.64 | 3.97 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.125 | 3.2 | 3.01 | 4.51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.141 | 3.6 | 3.37 | 5.04 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.154 | 3.9 | 3.66 | 5.43 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.172 | 4.4 | 4.05 | 6.07 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.188 | 4.8 | 4.40 | 6.57 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.218 | 5.5 | 5.03 | 7.44 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.250 | 6.4 | 5.72 | 8.51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 2-7/8 | 73 | 0.083 | 2.1 | 2.48 | 3.67 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.109 | 2.8 | 3.22 | 4.85 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.125 | 3.2 | 3.67 | 5.51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.141 | 3.6 | 4.12 | 6.16 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.156 | 4.0 | 4.53 | 6.81 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.172 | 4.4 | 4.97 | 7.45 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.188 | 4.8 | 5.40 | 8.08 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.203 | 5.2 | 5.90 | 8.70 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.216 | 5.5 | 6.14 | 9.16 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.250 | 6.4 | 7.03 | 10.51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.281 | 7.1 | 7.75 | 11.54 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 3-1/2 | 88.9 | 0.083 | 2.1 | 3.03 | 4.50 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.109 | 2.8 | 3.95 | 5.95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.125 | 3.2 | 4.51 | 6.76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.141 | 3.6 | 5.06 | 7.57 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.156 | 4.0 | 5.58 | 8.38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.172 | 4.4 | 6.12 | 9.17 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.188 | 4.8 | 6.66 | 9.96 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.216 | 5.5 | 7.58 | 11.31 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.250 | 6.4 | 8.69 | 13.02 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.281 | 7.1 | 9.67 | 14.32 | ● | ● | ● | ● | ● | ● | ● | |||||

| 0.318 | 8.1 | 10.85 | 16.14 | ● | ● | ● | ● | ● | ● | ||||||

| 管线管尺寸、单位重量 API SPEC 5L、GB/T9711、GOST 20295 | |||||||||||||||

| 外径 | 壁厚 | 单重 | Steel Grade 钢级 |

||||||||||||

| in. | mm | in. | mm | Ib/ft | kg/m | A25 | A | B | X42 | X46 | X52 | X56 | X60 | X65 | X70 |

| L175 | L210 | L245 | L290 | L320 | L360 | L390 | L415 | L450 | L485 | ||||||

| 4-1/2 | 114.3 | 0.083 | 2.1 | 3.92 | 5.81 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 0.125 | 3.2 | 5.85 | 8.77 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.141 | 3.6 | 6.57 | 9.83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.156 | 4.0 | 7.24 | 10.88 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.172 | 4.4 | 7.96 | 11.93 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.188 | 4.8 | 8.67 | 12.96 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.203 | 5.2 | 9.32 | 13.99 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.219 | 5.6 | 10.02 | 15.01 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.237 | 6.0 | 10.8 | 16.03 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.25 | 6.4 | 11.36 | 17.03 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.281 | 7.1 | 12.67 | 18.77 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.312 | 7.9 | 13.97 | 20.73 | ● | ● | ● | ● | ● | ● | ||||||

| 0.337 | 8.6 | 15.00 | 22.42 | ● | ● | ● | ● | ● | ● | ||||||

| 5-9/16 | 141.3 | 0.125 | 3.2 | 7.27 | 10.89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.156 | 4.0 | 9.01 | 13.54 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.188 | 4.8 | 10.79 | 16.16 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.219 | 5.6 | 12.50 | 18.74 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.258 | 6.6 | 14.62 | 21.92 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.281 | 7.1 | 15.85 | 23.50 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.312 | 7.9 | 17.50 | 25.99 | ● | ● | ● | ● | ● | ● | ● | |||||

| 0.344 | 8.7 | 19.19 | 28.45 | ● | ● | ● | ● | ● | ● | ||||||

| 6-5/8 | 168.3 | 0.156 | 4.0 | 10.79 | 16.21 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.172 | 4.4 | 11.93 | 17.78 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.188 | 4.8 | 12.99 | 19.35 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.203 | 5.2 | 13.92 | 20.91 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.219 | 5.6 | 14.98 | 22.47 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.25 | 6.4 | 17.02 | 25.55 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.28 | 7.1 | 18.97 | 28.22 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 0.312 | 7.9 | 21.04 | 31.25 | ● | ● | ● | ● | ● | ● | ● | |||||

| 0.344 | 8.7 | 23.08 | 34.24 | ● | ● | ● | ● | ● | ● | ||||||

| 0.375 | 9.5 | 25.03 | 37.20 | ● | ● | ● | ● | ● | |||||||

| 8-5/8 | 219.1 | 0.188 | 4.8 | 16.96 | 25.37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.203 | 5.2 | 18.26 | 27.43 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.219 | 5.6 | 19.66 | 29.48 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.25 | 6.4 | 22.36 | 33.57 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.277 | 7.0 | 24.70 | 36.61 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.312 | 7.9 | 27.70 | 41.14 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.322 | 8.2 | 28.55 | 42.65 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.344 | 8.7 | 30.42 | 45.14 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 0.375 | 9.5 | 33.04 | 49.10 | ● | ● | ● | ● | ● | ● | ||||||

| 0.438 | 11.1 | 38.30 | 56.94 | ● | ● | ● | ● | ● | |||||||

| 0.5 | 12.7 | 43.43 | 64.64 | ● | ● | ● | ● | ||||||||

| 0.531 | 13.5 | 46.00 | 68.45 | ● | ● | ● | ● | ||||||||

| 10-3/4 | 273.1 | 0.203 | 5.2 | 22.89 | 34.36 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.219 | 5.6 | 24.63 | 36.94 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.25 | 6.4 | 28.04 | 42.09 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.279 | 7.1 | 31.20 | 46.57 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.307 | 7.8 | 34.24 | 51.03 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.344 | 8.7 | 38.23 | 56.72 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 0.365 | 9.3 | 40.48 | 60.50 | ● | ● | ● | ● | ● | ● | ||||||

| 0.438 | 11.1 | 48.24 | 71.72 | ● | ● | ● | ● | ● | |||||||

| 0.5 | 12.7 | 54.79 | 81.55 | ● | ● | ● | ● | ● | |||||||

| 0.531 | 13.5 | 58.08 | 86.42 | ● | ● | ● | ● | ||||||||

| 0.543 | 13.8 | 59.30 | 88.24 | ● | ● | ● | ● | ||||||||

| 管线管尺寸、单位重量 API SPEC 5L、GB/T9711、GOST 20295 | |||||||||||||||

| 外径 | 壁厚 | 单重 | 钢级 | ||||||||||||

| in. | mm | in. | mm | Ib/ft | kg/m | A25 | A | B | X42 | X46 | X52 | X56 | X60 | X65 | X70 |

| L175 | L210 | L245 | L290 | L320 | L360 | L390 | L415 | L450 | L485 | ||||||

| 12-3/4 | 323.9 | 0.219 | 5.6 | 29.34 | 43.96 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.25 | 6.4 | 33.38 | 50.11 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.278 | 7.1 | 37.42 | 55.47 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.312 | 7.9 | 41.45 | 61.56 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.33 | 8.4 | 43.77 | 65.35 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.344 | 8.7 | 45.58 | 67.62 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.375 | 9.5 | 49.56 | 73.65 | ● | ● | ● | ● | ● | ● | ● | |||||

| 0.406 | 10.3 | 53.52 | 79.65 | ● | ● | ● | ● | ● | ● | ||||||

| 0.438 | 11.1 | 57.59 | 85.62 | ● | ● | ● | ● | ● | ● | ||||||

| 0.5 | 12.7 | 65.48 | 97.49 | ● | ● | ● | ● | ● | |||||||

| 0.531 | 13.5 | 36.91 | 54.92 | ● | ● | ● | ● | ||||||||

| 0.543 | 13.8 | 38.53 | 57.33 | ● | ● | ● | ● | ||||||||

| 0.551 | 14.0 | 39.63 | 58.97 | ● | ● | ● | ● | ||||||||

| 14 | 355.6 | 0.25 | 6.35 | 36.75 | 55.11 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.281 | 7.1 | 41.21 | 61.02 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.312 | 7.9 | 45.65 | 67.74 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.344 | 8.7 | 50.22 | 74.42 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.375 | 9.5 | 54.62 | 81.18 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.406 | 10.3 | 59.00 | 87.71 | ● | ● | ● | ● | ● | ● | ||||||

| 0.438 | 11.1 | 63.50 | 94.30 | ● | ● | ● | ● | ● | |||||||

| 0.469 | 11.9 | 67.84 | 100.82 | ● | ● | ● | ● | ● | |||||||

| 0.5 | 12.7 | 72.16 | 107.24 | ● | ● | ● | ● | ● | |||||||

| 0.531 | 13.5 | 40.68 | 60.53 | ● | ● | ● | ● | ||||||||

| 0.543 | 13.8 | 42.47 | 63.20 | ● | ● | ● | ● | ||||||||

| 0.551 | 14.0 | 43.68 | 65.00 | ● | ● | ● | ● | ||||||||

| 16 | 406.4 | 0.219 | 5.6 | 36.95 | 55.35 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 0.25 | 6.4 | 42.09 | 63.13 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.281 | 7.1 | 47.22 | 69.92 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.312 | 7.9 | 52.53 | 77.64 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.344 | 8.7 | 57.57 | 85.33 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 0.375 | 9.5 | 62.64 | 92.99 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 0.406 | 10.3 | 67.68 | 100.61 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 0.438 | 11.1 | 72.86 | 108.21 | ● | ● | ● | ● | ● | ● | ● | |||||

| 0.469 | 11.9 | 77.87 | 115.77 | ● | ● | ● | ● | ● | ● | ||||||

| 0.5 | 12.7 | 82.8 | 123.31 | ● | ● | ● | ● | ● | |||||||

| 0.531 | 13.5 | 46.72 | 69.52 | ● | ● | ● | ● | ||||||||

| 0.543 | 13.8 | 48.78 | 72.59 | ● | ● | ● | ● | ||||||||

| 0.551 | 14.0 | 50.18 | 74.67 | ● | ● | ● | ● | ||||||||

加工定制

为了给客户提供更完善的服务,金年会投入多种加工设备及人员,提升自身的加工能力。目前金年会能为客户提供的加工服务有车丝、压槽、缩径、焊接、钻孔、冲压等。客户还可以根据需要向金年会的工作人员提出要求,金年会的技术人员可以根据您的图纸帮你定制出所需的产品。

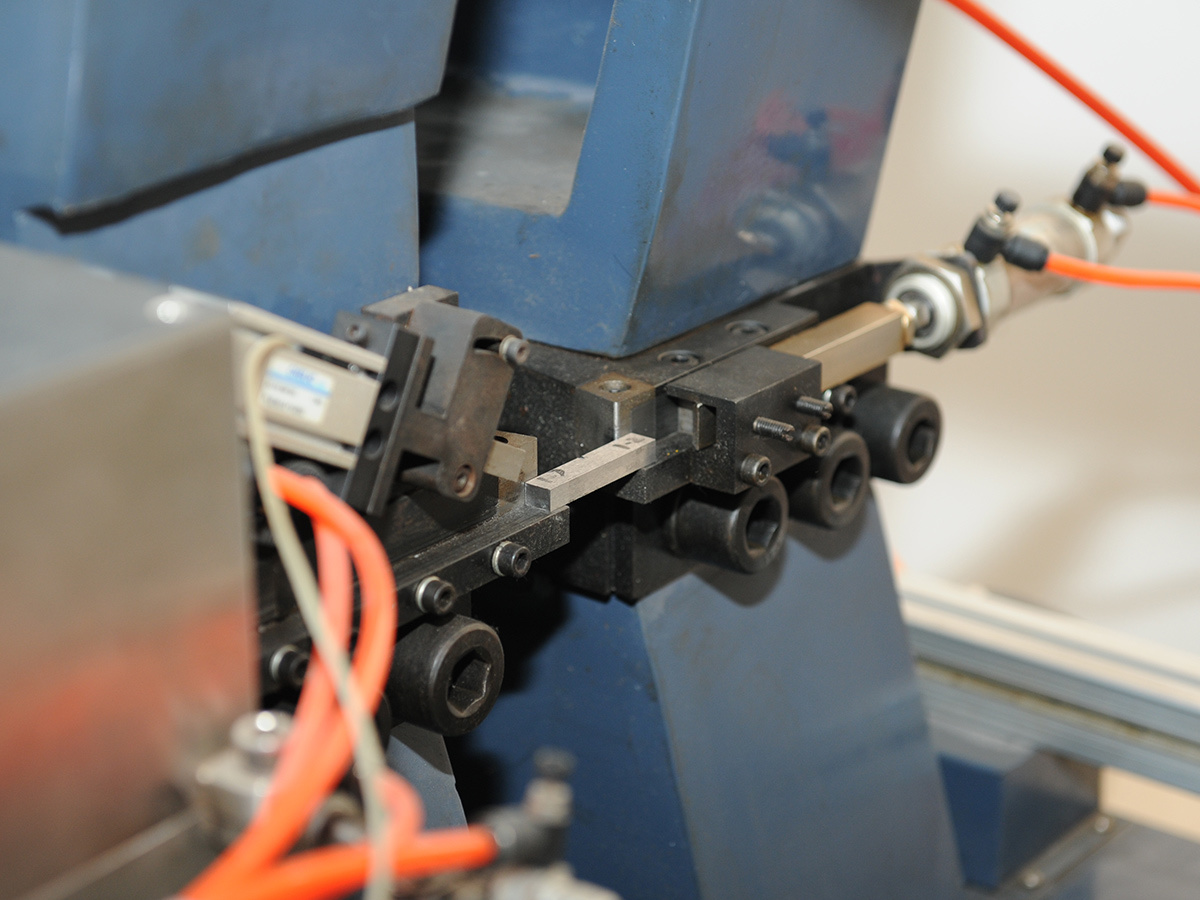

管端车丝

管端压槽

管端缩径

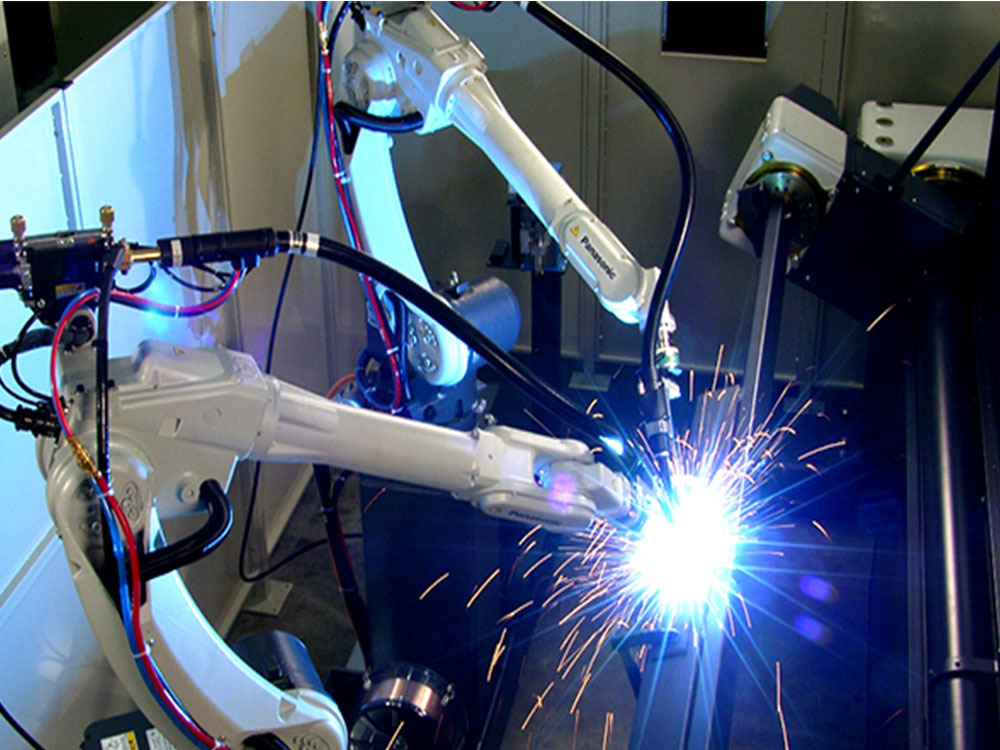

焊接装配

管体钻孔

管体冲孔

管体弯曲

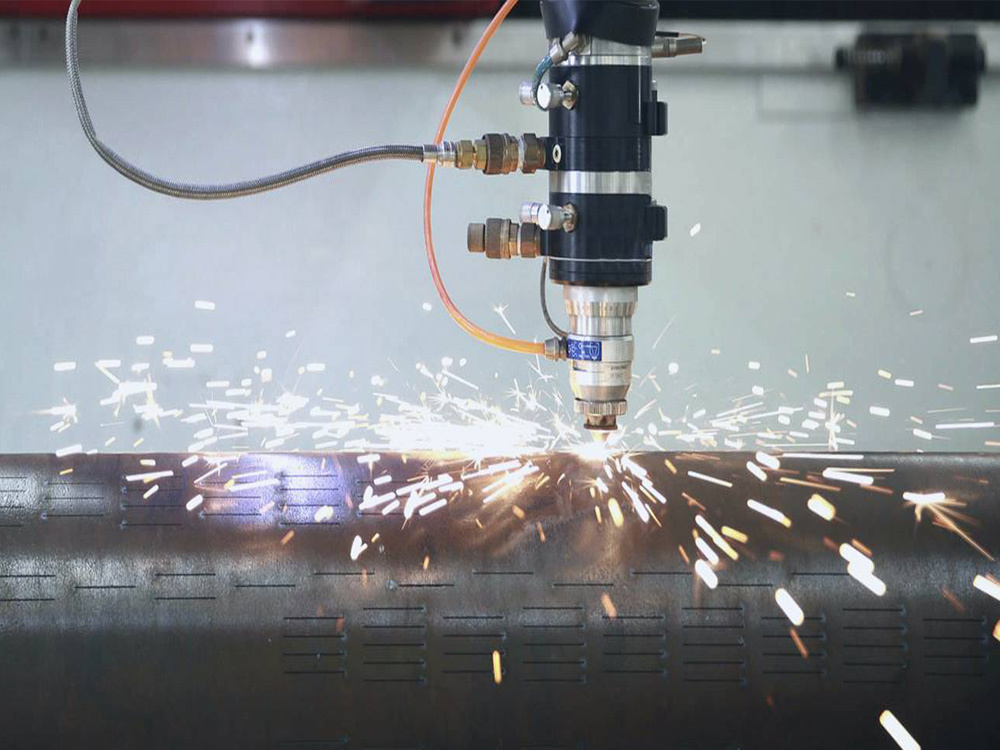

管体割缝

质量控制程序

合同评审

对于质量等级较高或客户有特殊要求的产品,在签订合同前,营销部组织相关人员对这些要求进行充分评审,确保客户要求可得到满足。需要时,由公司技术人员向客户进行解释并给出专业性建议。

来料检验

对入厂的原材料,由专职检验员按炉或批进行外观、尺寸和理化性能等方面的检验,确保原材料在投入生产前满足要求,为生产提供可靠的物料保证。对原料检验结果进行定期汇总分析和评审,作为供应商选择和评价的依据。

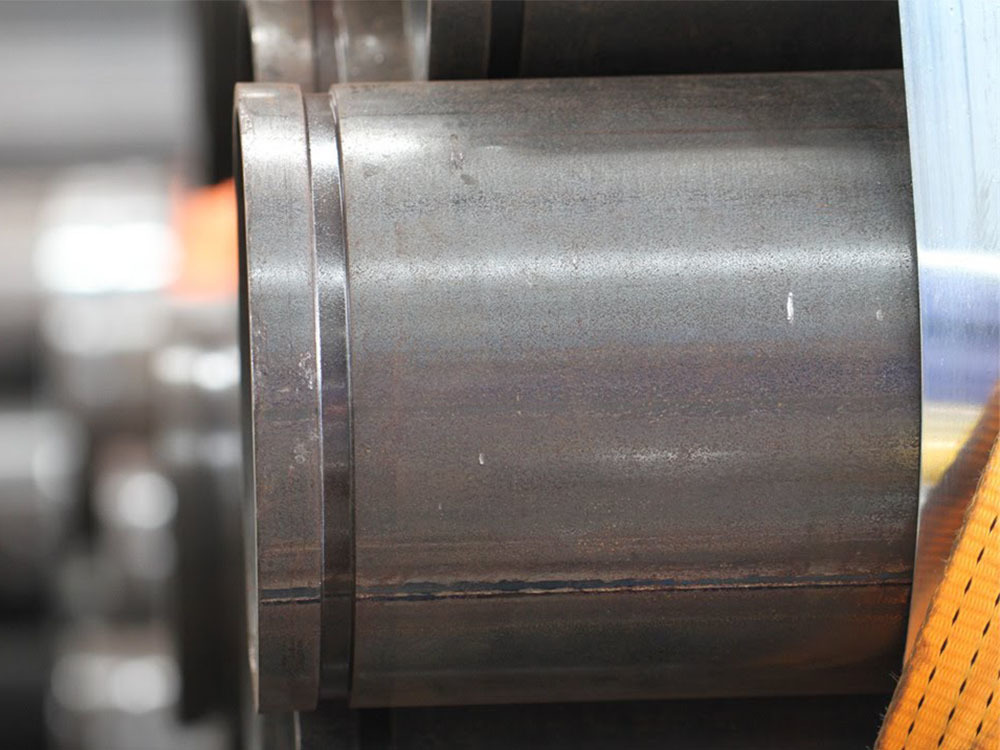

过程检验

为了确保金年会产出的钢管符合客户要求,对生产过程的各个关键控制点进行定期巡查、检查和监督,对特殊过程进行定期确认,确保每个过程均符合过程控制准则。对产品的关键特性由专职过程检验员和试验员进行检查,包括压扁试验、水压试验、无损检测、理化试验、尺寸检查、外观检查等,确保产品符合钢管接收准则。

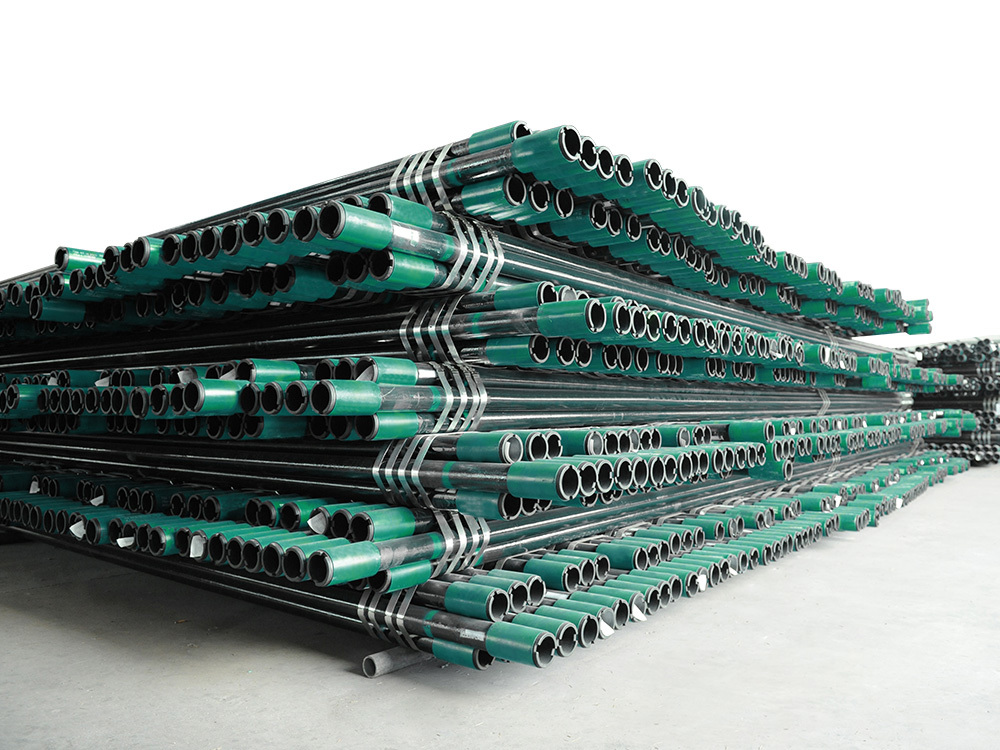

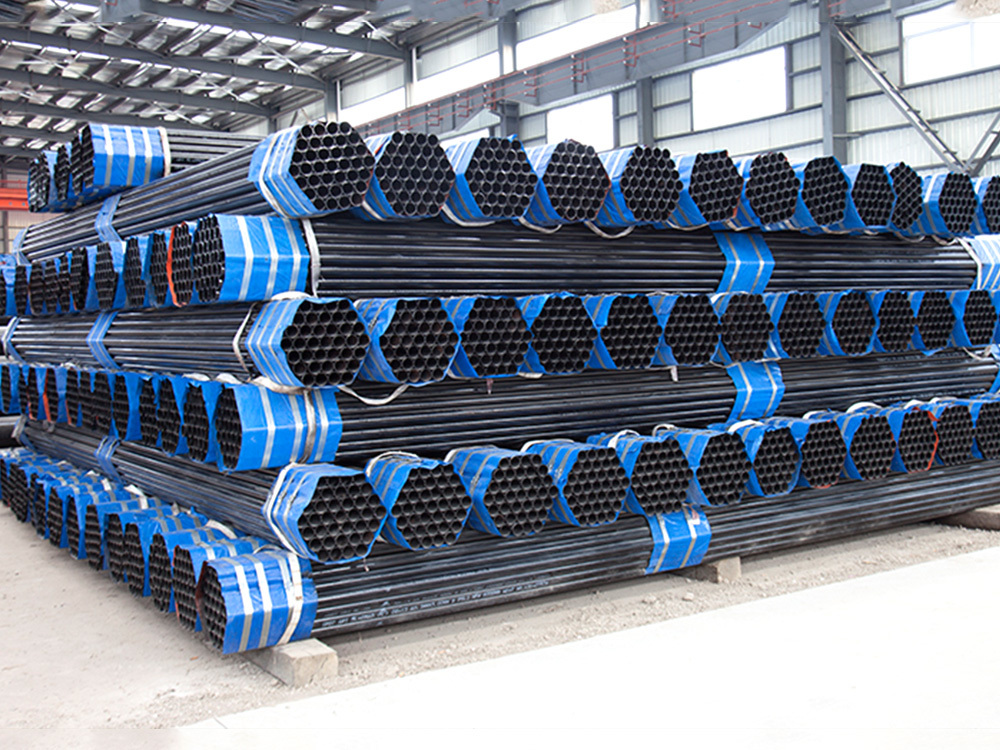

涂层、标记、包装

钢管生产完毕后,金年会会根据客户要求对钢管表面进行涂层处理,包括:黑漆、清漆、防锈油等,这些材料确保钢管在运输过程中起到短期防锈的效果。

为了确保钢管的可追溯性,在生产过程中对每支钢管进行唯一性管号标识或条码标识。在最终涂层后(需要时),根据客户和标准要求,在管体喷涂完整标记,在该过程中,操作工将逐一核对并转移唯一性管号标识,确保钢管的可追溯性。

产品的包装在运输环节对于产品的防护起到了至关重要的作用,所以金年会对此也十分关注。根据钢管的尺寸、涂层、加工类型等,金年会通常会使用到管帽、PVC包布、尼龙吊带、镀锌带、熏蒸木材等材料对钢管进行保护。同时,金年会的工程师还能根据客户的要求定制更为牢固、稳定、易装卸的产品包装设计解决方案。

最终检验

在钢管发货前,金年会的专职技术人员根据产品规范和质量计划要求,进行最终完整性检查,包括:生产和监视测量设备状态、人员、来料检查、过程检验、最终产品检验、包装、喷标等信息进行逐一核对,确保产品满足客户要求。在检验合格后,金年会的质保部门根据每一批发运的产品签发产品质量证明书。

产品过程检验

化学成分分析

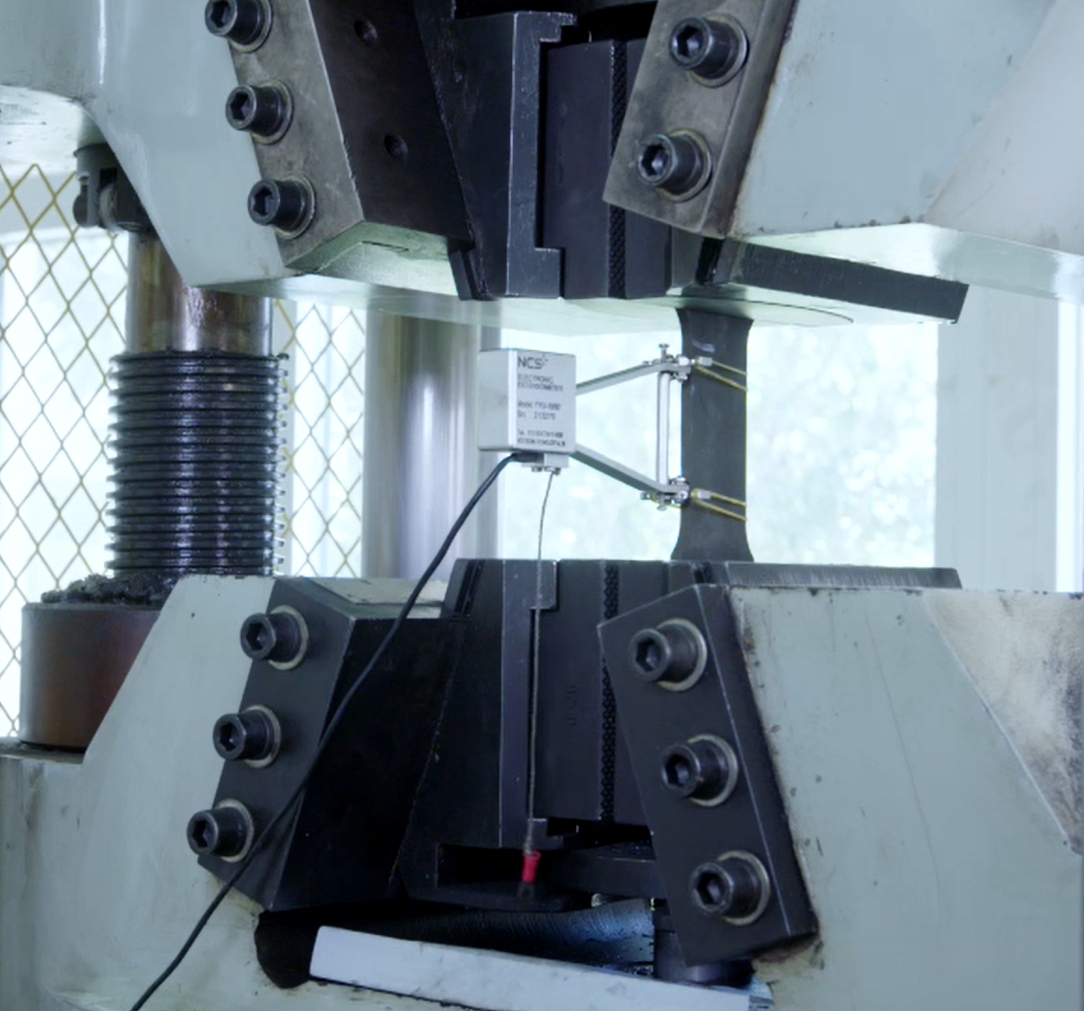

拉伸试验

夏比冲击试验

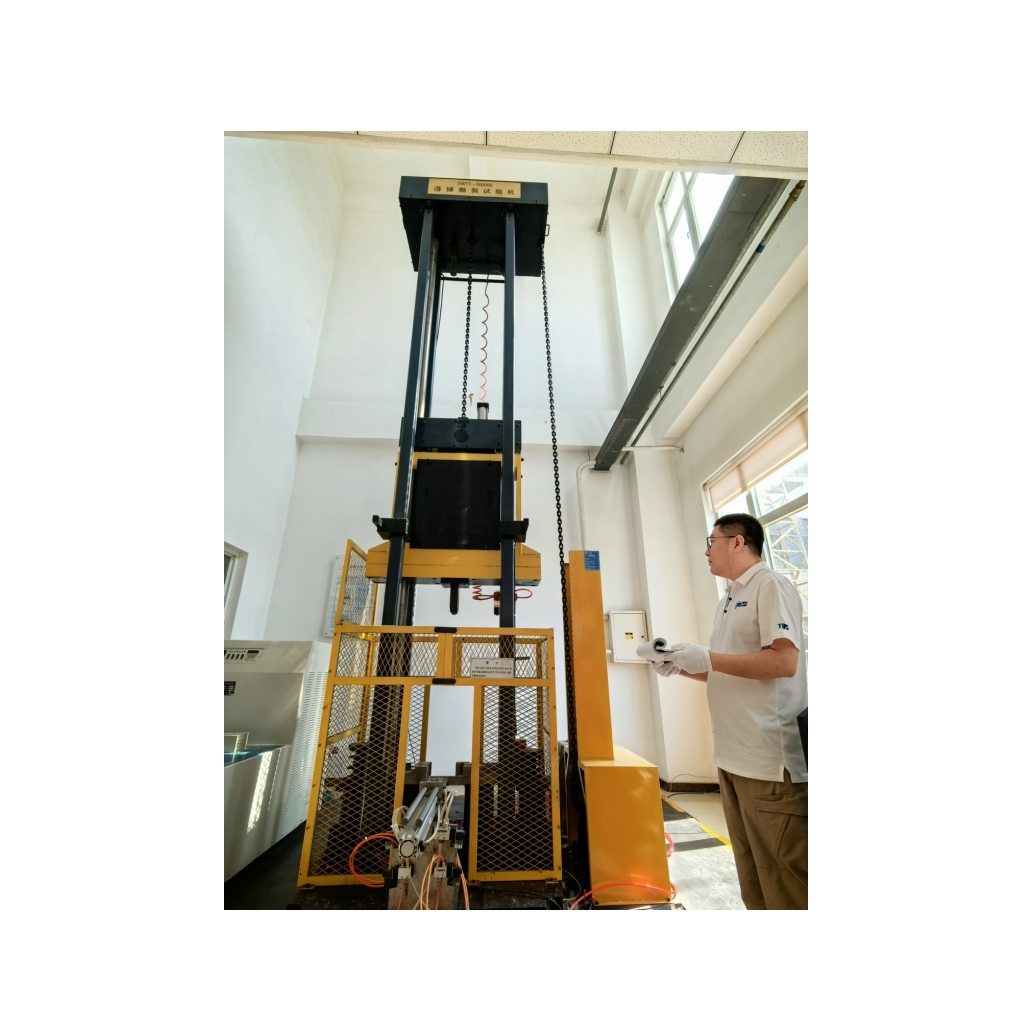

落锤撕裂试验

金相试验

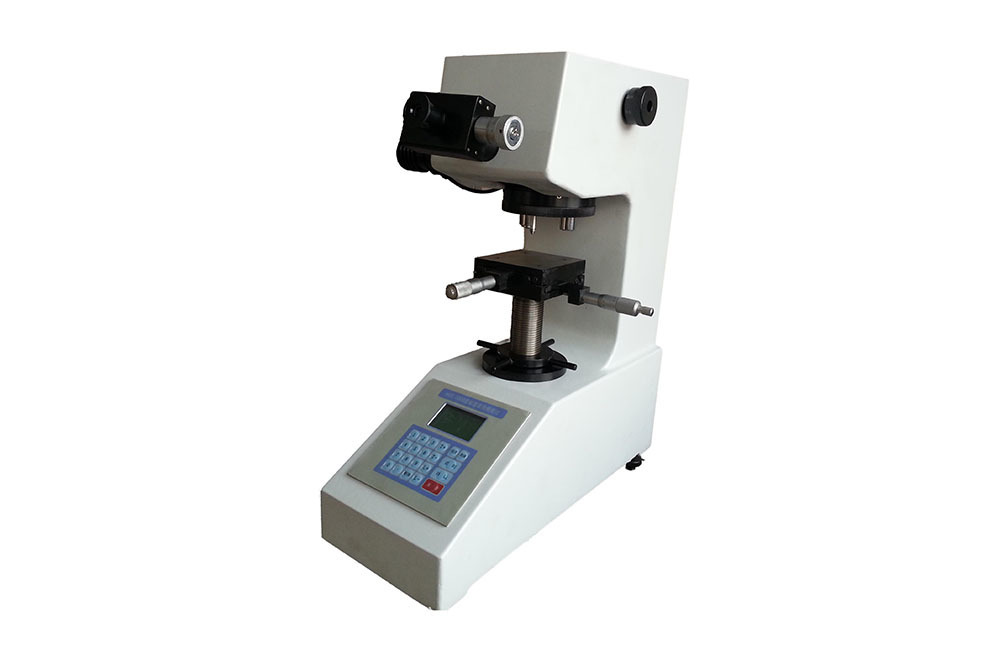

维氏硬度试验

在线咨询

相关产品